Our Facilities

CNC Milling

CNC Milling, CNC Wirecut, CNC Lathe, CNC Raid Drill & conventional Machines for Making all type of machined and press shop components including various jigs , fixture etc

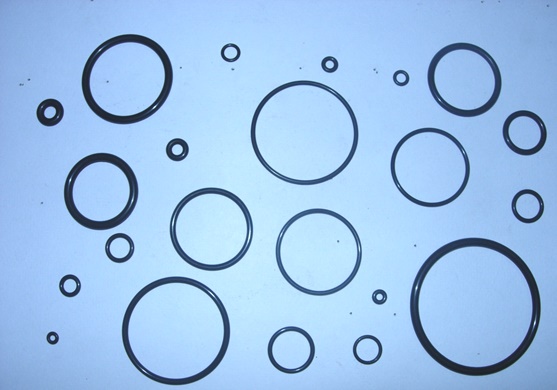

In-house MOULD Making Facility

We make all 90 and 45 degee parting line moulds for O-Rings, glands , Gaskets & Different shape of rubber parts

Mould Making is facilitated by CNC Machines Like CNC Lathe & CNC Milling in house.

CNC Lathe Machine

- Make : Lokesh Machine Tools

- Model No. : TL 20

- Max. Machine Diameter : 270 mm

- Max. Turning Length : 300 mm

- Spindle Speed : 45 - 4500 (RPM)

- Accuracy : ±0.01 mm

CNC Verticle Milling Centre

- Make : HASS

- Model No. : VMC TM2

- Work Table Size : 900 x 400 mm

- Stroke Size : 815 x 375 x 450 mm

- Accuracy : ±0.02 mm

CNC Wirecut EDM

- Make : Electronica Machine Tools

- Model No. : Electram EL: 20e (MAXICUTE)

- Table Size (WXD): 440 x 650 mm

- Stroke Size (XYZ) : 300 x 400 x 230 mm

- Accuracy : ±0.02 mm

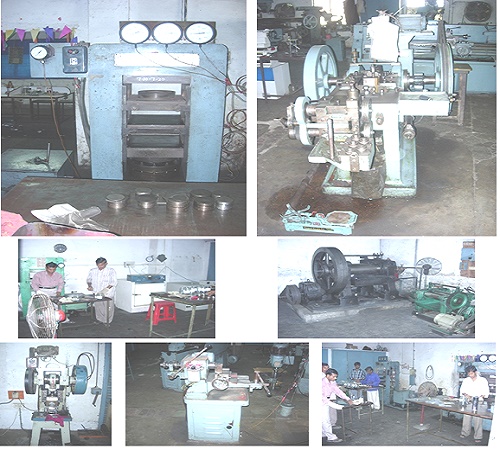

Tool Room

The Company has its own Tool Room comprising of all the necessary machines including CNC Wirecut Machine, HMT make Milling & Grinding Machines, GD Wheeler Lathe Machine etc. for making Rubber Moulding Tools as well as other necessary Jigs, Fixtures, Press Tools.

Production Shop

The Company is having its own Mixing Mill, Calendaring Machine, Rubber Moulding Hydraulic-Press Machines, Post Curing Ovens & full infrastructure for finishing of components. The Company also have all necessary machines for making machined, press shop components & items to be manufactured on CNC Wirecut Machine.

Test Laboratory

The Company has air-conditioned test laboratory equipped with all necessary measuring instruments and profile projector, tensile testing machine, ageing oven and all other necessary equipments for testing of rubber compounds and components.

Each batch of rubber compound is tested for its specification and only after obtaining satisfactory results, the rubber compound is released for manufacturing of components. Periodical tests on test slabs & buttons are also carried out to confirm the consistency of each batch of rubber compound.

Gauges & Packing

Each component is dimensionally checked (100%) using necessary special gauges. We make all the necessary gauges ourselves and the gauges can be made available to the user also for any verification. The items are individually packed in prescribed quality of envelopes.

We have in-house facility for making and sealing of prescribed quality of envelopes. Item and its Part No., Qty., material & material batch No. and its shelf life is indicated on the envelope.

Contact Us

Office

- G-6, Murli Bhawan, 10-A, Ashok Marg, Lucknow.

- 0522-2286579, 4068067

- 0522-2286422

- bpenglko@gmail.com

Factory

- 6, HAL Ancillary Estate, Ismailganj, Barabanki Road, Lucknow

- 9696441829 , 0522-2721394